Blog - Cavitation and process intensification

02/06/2023

White paper on cavitation technologies

If you read about hydrodynamic or acoustic cavitation and process intensification technologies you may find it interesting to read our white paper on cavitation technologies: what is cavitation, state of art of cavitation technologies, comparisons and key benefits.

Click and read free the white paper on cavitation technologies.

11/02/2023

Radio Veronica One interviews E-PIC S.r.l.

On Saturday, February 11th, 2023, Radio Veronica One interviewed E-PIC S.r.l. to briefly present its ROTOCAV hydrodynamic cavitator. Section dedicated to energy and sustainability.

The interview is available in Italian here.

12/05/2022

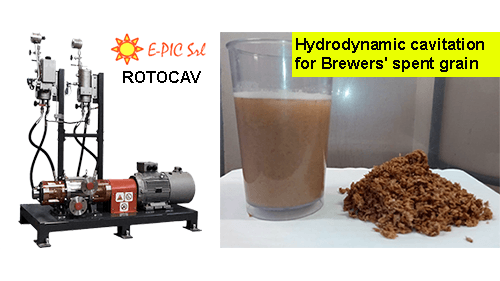

Hydrodynamic cavitation for Brewers' spent grain

Brewers' spent grain (BSG) is the most abundant and valuable by-product of beer-brewing. The alternative utilization of BSG has gained increased attention during recent years due to technological progress in its processing and the emergence of the concept of circular economy. BSG is characterized by a rich nutritional composition consisting of around 70% lignocellulosic fibrous material, 20% proteins, 10% lipids, in addition to vitamins, minerals, amino acids, and phenolic compounds.

The pretreatment stage of BSG biomass plays an important role in the efficiency of the extraction process and the final yield.

Due to the complicated natural plant cell wall composition, including cellulose, hemicellulose and lignin, which interlock together to form a recalcitrant structure, the utilization of lignocellulosic materials in biorefinery or in animal feed processes requires a right pretreatment: ROTOCAV hydrodynamic cavitator disrupts their crystalline structure and allow their fractionations, increases the specific area, total pore and micropore volume of the matrix.

The valorization of BSG through cavitation is environmentally friendly and sustainable.

Shear stress and cavitation promote the physical shredding of the biomass, increasing the available area, improving the valorization of the Brewers' spent grain.

With ROTOCAV you can:

- Obtain a higher yield with a faster extraction (saving time, energy and money);

- Valorize wastes, by converting by-products into valuable new animal food ingredients and nutrition supplements;

- Obtain high value products due to the mild operative process conditions.

30/03/2022

ROTOCAV: the hydrodynamic cavitator ATEX certified

In the extract industry, as well as in other industries, flammable fuilds have to be used: these areas could require ATEX certified equipment. To satisfy these needs we added to our gamma of products ATEX certified hydrodynamic cavitators, according to UNI CEI EN ISO 80079-36:2016 and CEI EN IEC 60079-0:2018.

Here is the solution for your needs, to treat and cavitate solutions and suspensions with flammable liquids.

15/06/2021

ROTOCAV hydrodynamic cavitator - New version, inspectable cavitation chamber

The new reactor is able to induce and control hydrodynamic cavitation on the treated suspensions, same as the traditional version, with some modifications to the design, to better meet the needs required in some specific industries (extraction and biomass treatment).

More into details, this new version comes with nozzles and a washing ring, to clean better the internals of the cavitation chamber at the end of each working cycle.

Moreover, the cavitation chamber can be easily opened for visual inspections, to ensure a complete cleaning between each working cycle, for different natural matrices and solvents.

The new version of this hydrodynamic cavitator is also available with ATEX certification for zone 2.

31/05/2021

CAVIBATCH: hydrodynamic cavitator for batch installations

The Cavibatch hydrodynamic cavitator induces and controls the cavitation phenomenon on a fluid or on a suspension in a tank.

The solution is designed and developed to work in batch, with small volumes (50 - 3000 L).

Easy, compact, simple solution: the system is immersed in the bulk of the liquid, which is forced to recirculate and pass through the elements inside the cavitation chamber. The treated product is subjected to shock waves, hot spots and cavitation events.