Blog - Cavitation and process intensification - p5

01/06/2017

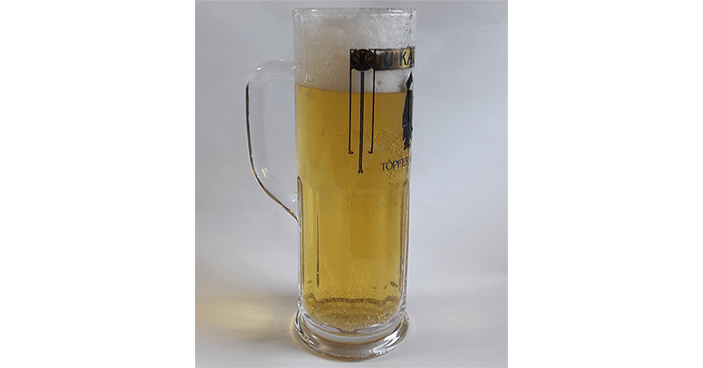

Hydrodynamic cavitation for the brewery industry

Cavitation treatment can decrease by 50% bittering and aroma hops usage! Our ROTOCAV-S can be installed in the mashing stage, without pre-milling the grains, or during the boiling stage when hops are added to the wort. Decrease the amount of hops even during dry hopping! Decrease also the saccarification temperature, cavitation speeds up the mass transfer!

25/05/2017

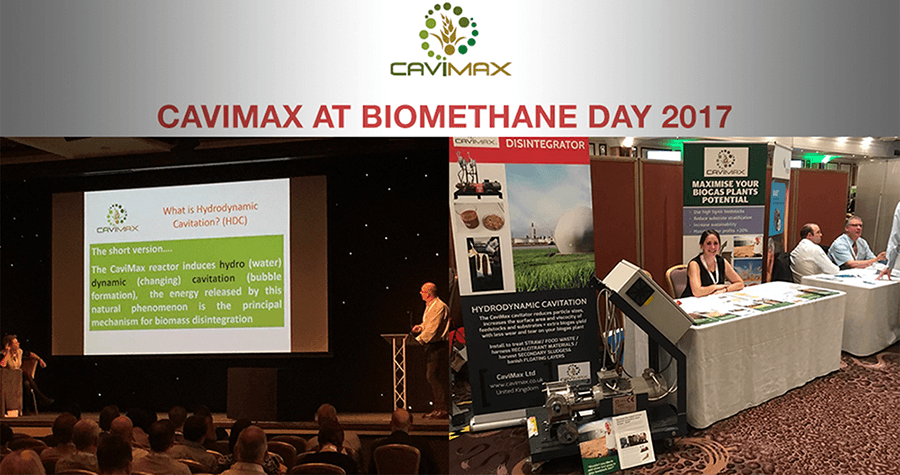

CAVIMAX at Biomethane Day 2017

CAVIMAX team presenting at Biomethane Day 2017 - Birmingham. Owen explaining hydrodynamic cavitation applied to biogas production and biomass treatment to increase production of methane, biomass yield and possibility to treat fibrous and "difficult" biomasses, and Emma at the stand responding to visitors' questions. Our hydrodynamic cavitator is ideal to boost existing biogas plants and for new biomethane plants!

08/05/2017

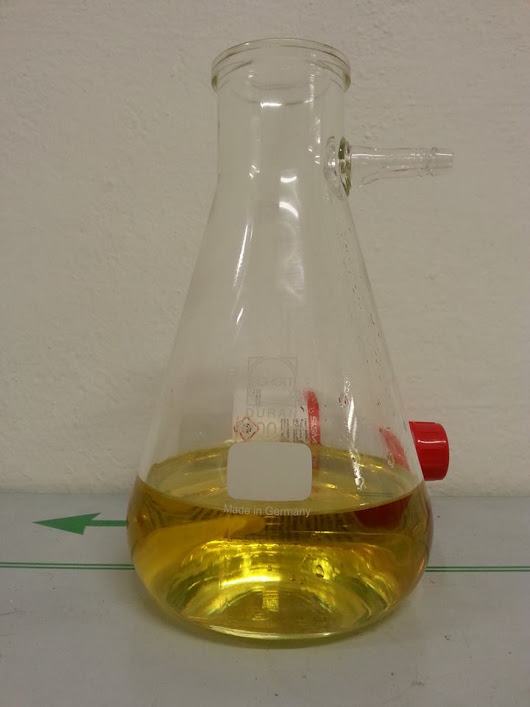

Mousse and ROTOCAV cavitator

03/05/2017